What is DSEAR?

DSEAR stands for the Dangerous Substances and Explosive Atmospheres Regulations 2002 and is applicable to all industry sectors.

Dangerous substances not only increase the risk to persons that work at a facility or site, but also to those in surrounding areas that lay within the affected envelope of any potential hazardous event (for example members of the public). Such events can include fire, explosion, and metal deterioration as a result of, or leading to, loss of containment. DSEAR is a legislative instrument which places duties on employers (and the self-employed) to protect people from these risks.

What are Dangerous Substances?

Dangerous substances are any substances used or present at work that could, if not properly controlled, cause harm to people as a result of a fire or explosion or loss of containment. They are found in nearly all workplaces and include such things as solvents, ethanol, paints, varnishes, flammable gases and vapours (such as liquid petroleum gas – LPG), dusts from machining and sanding operations, dusts from foodstuffs, pressurised gases and substances corrosive to metal.

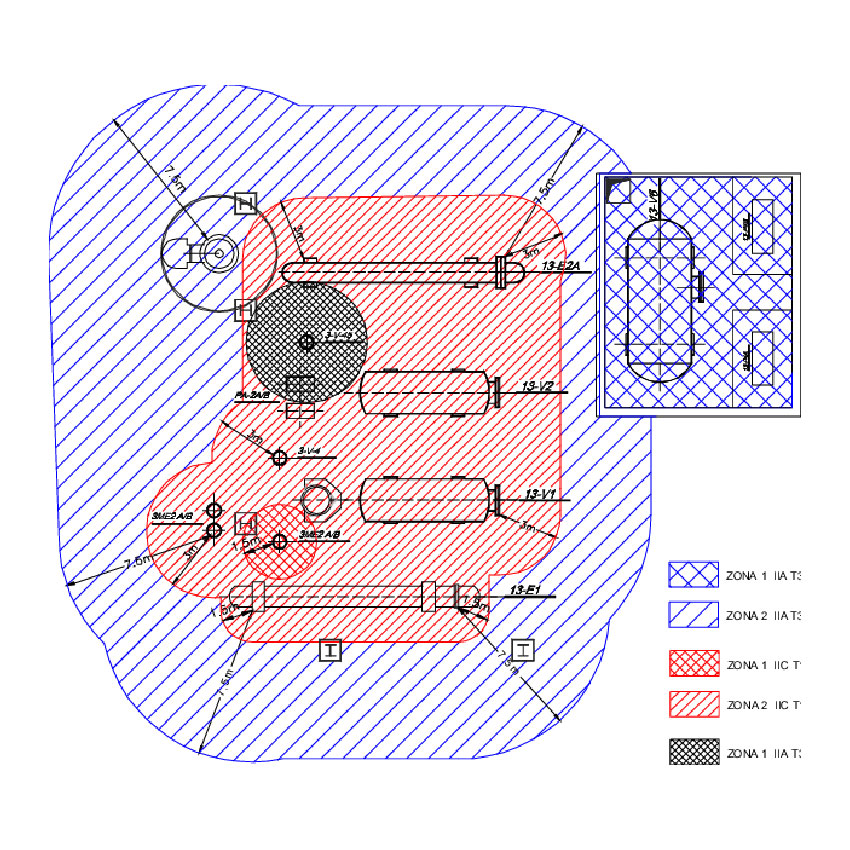

Typical Area Classification Diagram

What does DSEAR Require you to do?

Employers must: –

- Find out what dangerous substances are in your workplace and what the risks are,

- Put control measures in place to either remove those risks or, where this is not possible, control them,

- Put controls in place to reduce the effects of any incidents involving these substances,

- Prepare plans and procedures to deal with accidents, incidents and emergencies involving these substances,

- Make sure employees are properly informed about, and trained to control or deal with the risks from these substances,

- Identify and classify areas of the workplace where explosive atmospheres may occur and avoid ignition sources (from unprotected equipment, for example) in those areas.

Holme Beck Engineering Ltd

Who we are

The engineering team at Holme Beck Engineering Ltd have over 35 years of experience working with potentially explosive atmospheres. We can carry out, organise, or audit the full lifecycle functions:

- Risk assessment / Hazardous area classification,

- Fixed electrical installations,

- Moveable electrical equipment,

- Lightning in relation to structures with a risk of explosion and loss of control,

- Electrostatic hazards,

- Radio frequency radiation,

- Isolating joints, for example in cathodic protection systems,

- Mitigation of releases using: –

- Flammable and toxic gas detection,

- Fire detection.

- Records (drawings, documentation, and reports),

- Gap analysis and review (Equipment, systems, and coverage),

- Design, specification, and procurement,

- Test and inspection (Equipment, systems, and coverage),

- Management of change,

- Decommissioning and removal.

Standards and Guidance we use

Our Engineers are familiar with and utilise BS EN 60079 and BS EN ISO/IEC 80079 series of standards supported by appropriate industrial sector codes and guides to obtain a usable practical result for you, such as and among others: –

- L138 Health and Safety Executive – Dangerous Substances and Explosive Atmospheres Regulations 2002. Approved code of practice and guidance: 2015,

- BS EN 1127-1:2019 Explosive atmospheres. Explosion prevention and protection – Basic concepts and methodology,

- BS 6656:2002 Assessment of inadvertent ignition of flammable atmospheres by radio frequency radiation

- Energy Institute – EI model code of safe practice Part 15 Edition 4: Area classification for installations handling flammable fluids,

- Institution of Gas Engineers and Managers – IGEM/SR/25 Edition 2: Hazardous area classification of Natural Gas installations,

- Institution of Chemical Engineers (IChemE) – Dust explosion prevention and protection.